A pressurisation unit is a mechanical means of replacing water that has been lost through system leakage and to maintain the system design fill pressure in sealed heating and chilled water systems. This system generally eliminates the need for a cold water storage system in a roof. All sealed heating systems have to have an interlock circuit so that the boilers are cut out if the unit is at fault. Incorrect calibration of the unit settings or pre charging of the expansion vessels will cause the system to malfunction.

Conventional heating systems are provided with a feed and expansion tank, normally positioned above the highest point in the system. This feeds the system with water, accommodates expansion and replaces losses due to evaporation.

This arrangement causes air to be absorbed into the water with resultant corrosion of heat exchangers, pipework and boilers. A sealed system limits air intake and corrosion to a minimum and only needs fresh water make-up to replace any losses caused by leakage. Higher flow temperatures may be used in sealed systems which, with larger temperature drops, permit lower water circulation rates, smaller pumps and reductions in pipework sizes, all with obvious cost-savings.

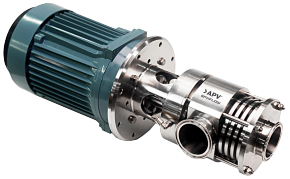

AxFlow UK Ltd has over 50 years of experience in selling and designing Pressurisation Units. As with booster sets we can provide units for a wide range of services from the small domestic property up to the largest commercial applications such as hospitals, hotels and factories. We specialise in the design and construction of complex pressurisation solutions for more demanding applications, where our systems design and pump expertise can be best utilised.

Our technical sales department will size booster sets based upon building type & diversity with advice on the best operation & storage to suit the duty. Once the booster set has been sized we can offer an installation and commissioning service via our service department (link to service page)

__________________________________________________________________________

Why Choose AxFlow (Building Services) UK Ltd?

The AxFlow Group is the largest distributor of positive displacement pumps and related products and services in Europe. The company represents world-leading suppliers, and adds considerable customer value by industrial know-how, fast and reliable deliveries and a wide range of technical services.

We are also one of the leading pump maintenance companies in the UK, with services from pump maintenance, installation, repairs upgrades. We are full insured and IOS accredited to give you peace of mind. Our friendly and helpful staff will provide you with a professional fast response.

- On all refurbishment projects we check the actual duty requirement to ensure the complete system is correctly specified we don't just replace the pressurisation sets like for like.

- We use IE-3 motors and variable speed drives to minimise power consumption and prolong the life of the pressurisation pumps.

- We recognise that a pressurisation system is about more than just the pumps – so we ensure the pipework, tanks and valves are all in a good working condition and operating correctly.