How to maintain centrifugal pumps

Centrifugal pumps are among the most widely used pump types in industry due to their simplicity, efficiency, and ability to handle a broad range of fluids.

However, to ensure long service life and reliable operation, they require regular inspection, proper lubrication, and proactive performance monitoring.

A structured maintenance program prevents unplanned downtime, reduces energy costs, and maintains hydraulic efficiency.

Routine Inspection and Monitoring

Daily / Weekly Checks

-

Inspect for leaks at the mechanical seal, casing joints, and drain plugs.

-

Monitor vibration and noise: Unusual vibration often indicates misalignment, bearing wear, or cavitation.

-

Check discharge pressure and flow rate: A drop in either can signal impeller damage, blockage, or wear ring erosion.

-

Observe pump temperature: Excessive heat may indicate bearing failure, overloading, or restricted flow.

-

Monitor motor current draw: A rising amp reading can point to hydraulic imbalance or frictional resistance.

Performance Trend Analysis

-

Record operating parameters—flow, head, power, and efficiency—regularly.

-

Compare with the pump’s original performance curve to detect early degradation.

-

Conduct vibration analysis and thermography to identify mechanical or electrical issues early.

Lubrication and Bearings

-

Check bearing lubrication at manufacturer-specified intervals.

-

For grease-lubricated bearings, apply only the correct quantity and grade—over-greasing can cause overheating.

-

For oil-lubricated bearings, maintain oil level and quality; replace if contaminated or discoloured.

-

-

Monitor bearing temperature and listen for abnormal noise, which indicates wear or lack of lubrication.

-

Always use high-temperature or anti-oxidation lubricants for pumps handling hot fluids.

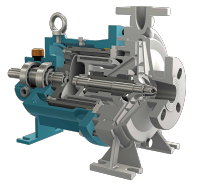

Shaft Alignment and Coupling

-

Misalignment between the pump shaft and motor is one of the most common causes of vibration and premature bearing failure.

-

Check alignment after installation, thermal expansion, or any maintenance involving the drive system.

-

Inspect couplings for cracks, fatigue, and wear; replace flexible elements as needed.

-

Ensure all mounting bolts are tight and that the pump baseplate is free from distortion or soft foot conditions.

Seal and Packing Maintenance

-

Mechanical Seals:

-

Inspect regularly for leakage—minor weeping may be acceptable, but continuous drips indicate wear.

-

Check seal flush or cooling lines for blockages or loss of flow.

-

Replace seal faces, O-rings, or bellows when worn or chemically degraded.

-

-

Gland Packing (if fitted):

-

Adjust to allow slight leakage for lubrication and cooling.

-

Replace if leakage becomes excessive or packing is burnt or hardened.

-

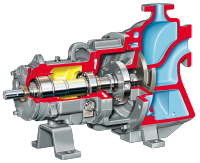

Impeller, Wear Rings, and Casing

-

Periodically inspect the impeller for corrosion, erosion, or buildup of solids.

-

Clean or replace the impeller if efficiency drops or vibration increases.

-

Check wear ring clearances—excessive clearance reduces efficiency and can lead to cavitation.

-

Inspect the pump casing for scaling, pitting, or cracks, especially in abrasive or corrosive services.

Suction and Discharge System

-

Keep suction strainers and filters clean and free of debris.

-

Ensure adequate Net Positive Suction Head (NPSH) to avoid cavitation damage.

-

Check suction and discharge valves for proper operation and tightness.

-

Verify that suction piping is airtight—air ingress causes cavitation and priming issues.

Preventive Maintenance Schedule

| Frequency | Maintenance Task |

|---|---|

| Daily / Weekly | Inspect for leaks, monitor vibration, and check pressure and temperature |

| Monthly | Check alignment, lubrication levels, and coupling condition |

| Quarterly | Inspect impeller, wear rings, and seals |

| Annually | Overhaul bearings, verify clearances, and test performance curve |

A consistent preventive maintenance routine greatly reduces the risk of costly breakdowns.

Long-Term Overhaul

Every 1–2 years (depending on service conditions):

-

Disassemble and clean all wetted components.

-

Replace worn bearings, seals, and wear rings.

-

Check shaft straightness and balance of the impeller.

-

Reassemble using new gaskets and ensure precise alignment before commissioning.

-

Perform a hydrostatic and performance test to verify rebuild quality.

Storage and Standby Maintenance

When a pump is out of service:

-

Drain all liquids and dry the internals to prevent corrosion.

-

Coat metallic surfaces with a protective oil film or corrosion inhibitor.

-

Rotate the shaft periodically to prevent bearing brinelling and seizing.

-

Store in a dry, vibration-free location with sealed inlet and outlet ports.

Proper maintenance of centrifugal pumps is essential to ensure their reliable performance and extend their lifespan. Regular maintenance includes several key steps. First, routine inspections of the pump's components, such as the impeller, casing, and seals, should be conducted to identify any signs of wear or damage. Second, monitoring fluid levels and checking for leaks helps prevent pump failure and inefficiencies. Third, keeping the pump and surrounding area clean helps prevent clogging and contamination. Regularly lubricating bearings and checking alignment ensures smooth operation. Additionally, following the manufacturer's maintenance guidelines, scheduling periodic maintenance, and promptly addressing any issues will contribute to the pump's efficiency and longevity. Proper maintenance not only minimizes downtime and repair costs but also enhances the pump's performance, providing reliable and efficient fluid handling for a wide range of applications.