How to maintain circumferential piston pumps

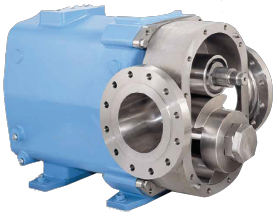

Circumferential piston pumps—also known as circumferential pumps or rotary lobe-style pumps—are precision-engineered positive displacement pumps used for hygienic, viscous, and shear-sensitive fluids.

Although they are robust and low-maintenance by design, regular inspection, lubrication, and correct alignment are essential to maintain efficiency, prevent wear, and ensure reliable long-term operation.

Routine Inspection and Performance Monitoring

Daily or Weekly Checks

-

Inspect for leaks around seals and casing joints.

-

Monitor for vibration or unusual noise—these can indicate rotor contact, misalignment, or bearing wear.

-

Check product temperature and discharge pressure for signs of excessive shear or restriction.

-

Visually inspect the pump head for residue or buildup that may affect performance, particularly in food or pharmaceutical processes.

Performance Indicators

-

A gradual drop in flow rate or increase in motor load may signal internal wear or incorrect rotor timing.

-

Consistent monitoring of energy consumption and output pressure helps identify early maintenance needs before failures occur.

Lubrication and Bearings

-

Timing gears (in the gearbox) require periodic oil checks and replacement per the manufacturer’s schedule—usually every 3,000–5,000 hours of operation.

-

Use the recommended gear oil grade and volume to ensure proper lubrication of timing gears and bearings.

-

For pumps operating in high-temperature or corrosive environments, verify that seals and lubrication materials are chemically compatible with the process fluid.

-

If the pump has grease-lubricated bearings, apply fresh lubricant at intervals recommended in the service manual. Avoid over-greasing.

Shaft Seals and Elastomers

-

Inspect mechanical seals or packing glands for leakage or wear. Replace seals if fluid or product is observed at the seal faces.

-

Regularly check O-rings and gaskets for cracks, hardening, or chemical degradation.

-

Always use OEM replacement seals and elastomers to maintain hygienic and pressure ratings.

-

For pumps in CIP/SIP systems, ensure seals are rated for the cleaning chemicals and temperatures used.

Rotor and Timing Gear Maintenance

-

The rotors (pistons) must be synchronized precisely via the timing gears so that they do not touch each other or the casing.

-

Check rotor clearances and timing alignment during annual maintenance or after any disassembly.

-

Excessive wear on the timing gears, shafts, or bearings can cause rotor contact, leading to product contamination or damage.

-

If rotors or shafts are replaced, always re-time the pump following manufacturer instructions before restarting.

Cleaning and Hygiene Maintenance

-

For food, beverage, and pharmaceutical use, ensure the pump is cleaned using CIP (Clean-in-Place) or SIP (Sterilize-in-Place) procedures where applicable.

-

Avoid prolonged dry running during cleaning cycles — these pumps rely on product or cleaning fluid for lubrication.

-

Disassemble and inspect internal surfaces periodically to confirm there is no residue, scale, or microbial buildup.

-

Maintain a record of cleaning cycles and inspections for traceability in hygienic applications.

Alignment and Drive System

-

Misalignment between the pump shaft and motor can cause vibration, seal wear, and bearing failure.

-

Check and correct alignment after installation, transportation, or any maintenance that involves coupling removal.

-

Inspect couplings for fatigue, wear, or cracking, and replace flexible elements as needed.

Storage and Standby Maintenance

When the pump is out of operation for extended periods:

-

Flush with a neutral, non-reactive cleaning fluid to remove product residue.

-

Drain and dry the pump to prevent corrosion or microbial growth.

-

Fill with a food-grade preservative oil if recommended for your application.

-

Rotate the shafts manually every few weeks to prevent sticking and maintain lubrication on internal surfaces.

Preventive Maintenance Schedule

| Frequency | Maintenance Task |

|---|---|

| Daily/Weekly | Inspect seals, check for leaks or vibration |

| Monthly | Check oil level and lubrication system |

| Quarterly | Inspect couplings, alignment, and bearing temperature |

| Annually | Verify rotor clearances, re-time gears, replace worn seals and bearings |

Following a preventive maintenance plan minimizes unplanned downtime and extends the service life of the pump.

|

|