How to select metering pumps

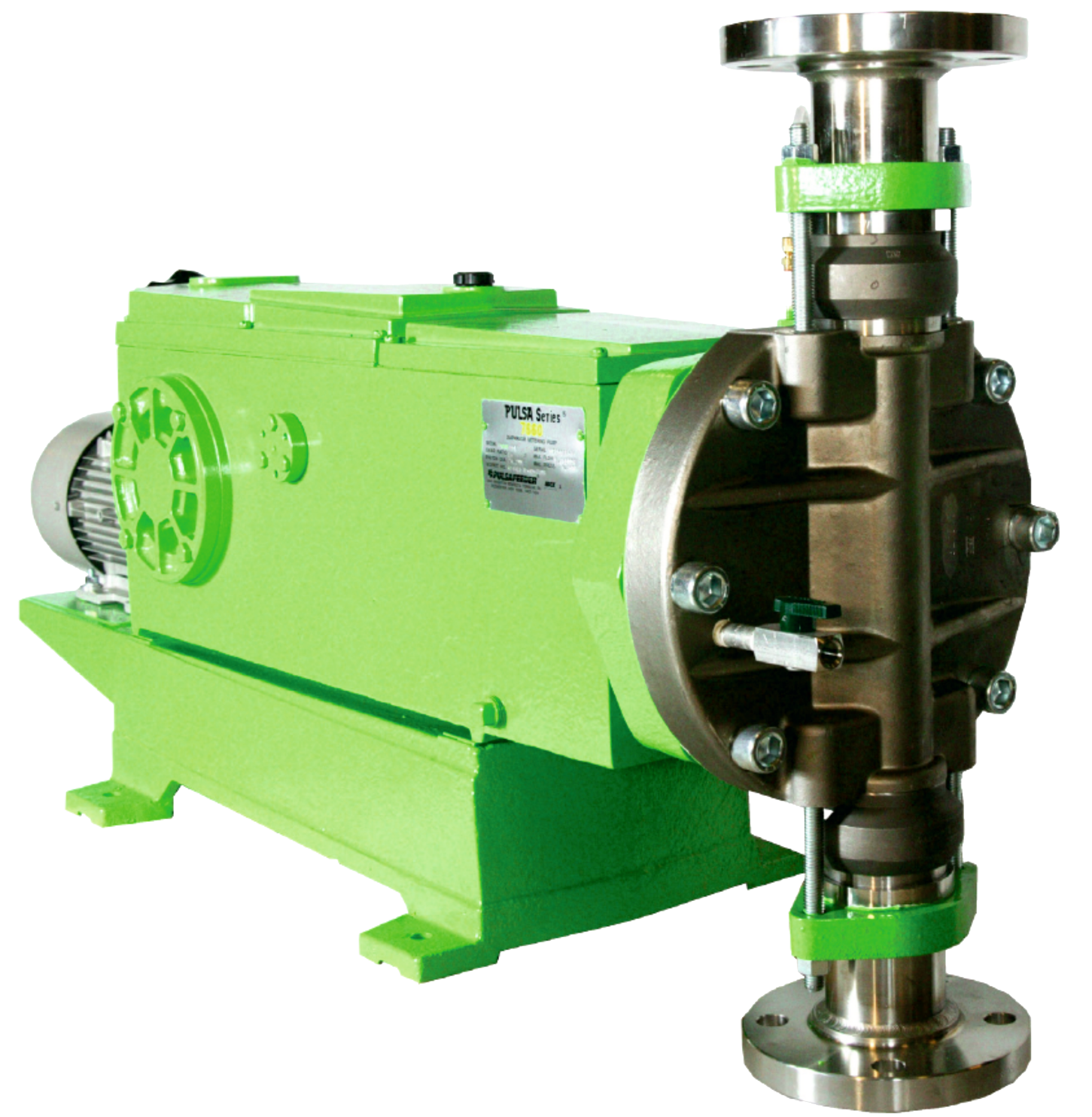

There are a range of things to consider when considering which type of metering pump is best suited for your application. Volumes and pressures of materials pumped through this equipment may vary greatly for different situations, but it must always be precise.

Specifications to consider when selecting Axial Flow pumps:

- Flow rate: Tends to be one of the most crucial factors to consider. Knowing your desired flow rate is key in selecting the appropriate equipment. A good idea is to make your maximum expected flow rate no more than 90% of the pump’s capacity, which will allow for flexibility in the case of small increases if needed.

- Environment of operation: Where will the equipment be operating? Is the metering pump going to be outdoors in direct sunlight? Or will it be exposed to extremely low temperatures? The operating environment will significantly impact pump performance. If you plan for the pump to be operate in lower temperatures for example, it is suggested that you ensure the fluid being pumped will not freeze at that temperature.

- Fluid properties: The composition of fluid you intend to pump is also rather important when selecting your metering pump size & type. This type of pump can be engineered to handle a variety of viscosities, however a number of things may have to be altered as the fluids get more viscous. Thicker fluids tend to require the use of special fluid ends. Extremely thick liquids that contain some solids may even require special diaphragms in order to effectively operate.

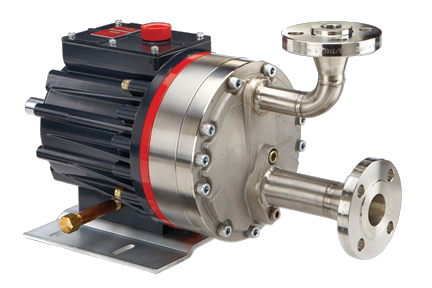

- Pump material: The parts that make up these metering pumps must be able to withstand the conditions they will be exposed to. Many industries handle corrosive chemicals or abrasive materials that require more heavy-duty pump components. If you are dealing with this type of fluid, you many need to explore parts made of something like stainless steel.

Manually controlled or Automatically controlled flow rate

Automatically Controlled Flow Rate: Metering pump flow rate can be controlled automatically by electric or pneumatic positioners which change the pump stroke length, or by variable speed drives which change the stroking speed.

Manually Controlled Flow Rate: Metering pump flow rate can be manually altered by a micrometer dial. Adjusting this dial changes the pump’s stroke length allowing the pump to be operated anywhere between 10% and 100% of its rated flow capacity.