At AxFlow, we have an extensive range of pumps suitable for Ethylene Glycol and Propolyene Glycol pumping applications for use across industries in the UK.

Our choice of pumps not only includes cast iron circulation pumps and ATEX certified stainless steel pumps but also magnetic drive pumps that reduce the thermal transfer between the motor and fluid in the pump chamber. We can handle liquids with temperatures as low a - 150 oC.

Glycol-based fluids—such as ethylene glycol and propylene glycol—are widely used as heat transfer agents, antifreeze solutions, and de-icing fluids in industries including HVAC, refrigeration, chemical processing, and renewable energy.

Because glycol solutions vary in viscosity, temperature, and concentration, choosing the right pump and maintaining it properly is key to efficient, reliable, and leak-free operation.

Understanding Glycol and Its Properties

Glycol is a viscous, water-miscible liquid that provides freeze protection and thermal stability. However, its physical properties—especially viscosity and lubricity—change significantly with temperature and concentration:

-

Higher glycol concentrations increase viscosity and reduce flow efficiency.

-

Low-temperature glycol can become thick, requiring more power to pump.

-

Hot glycol can thin out, affecting pump suction performance and seal life.

-

Some glycol blends are mildly corrosive to certain metals and elastomers.

Because of this variability, the pump must be matched to the fluid’s temperature, viscosity, and chemical compatibility.

Suitable Pump Types for Glycol

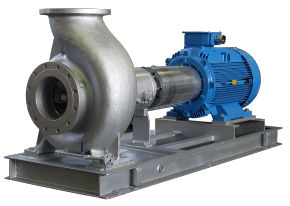

1. Centrifugal Pumps

-

Best for low- to medium-viscosity glycol solutions (up to ~40% concentration).

-

Commonly used in HVAC, cooling loops, and process circulation.

-

Stainless steel or bronze construction is preferred for corrosion resistance.

-

Mechanical seals should use EPDM or Viton® elastomers, compatible with glycol.

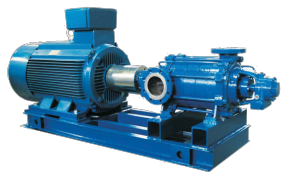

2. Positive Displacement Pumps

Used for higher concentrations or viscous mixtures, particularly in process or dosing systems.

-

Gear Pumps: Ideal for metered glycol dosing or transfer at steady flow rates.

-

Screw Pumps: Provide smooth, pulse-free delivery for high-viscosity or pressurized systems.

-

Diaphragm or Peristaltic Pumps: Suitable for precise dosing or handling corrosive glycol blends where seal-less design is preferred.

Key Design Considerations

-

Viscosity and Flow Rate:

Select a pump capable of maintaining flow at the lowest expected temperature—when glycol is most viscous. -

Materials of Construction:

-

Recommended metals: Stainless steel, bronze, or cast iron (depending on concentration and additives).

-

Avoid zinc, galvanized steel, or certain aluminium alloys, which may corrode in glycol service.

-

-

Seals and Elastomers:

Use EPDM, Viton®, or PTFE seal materials to ensure long service life and chemical resistance. -

Temperature Range:

Pumps should withstand operating temperatures from -40°C to +120°C, depending on the system. -

Priming and NPSH:

Ensure proper suction head or self-priming design—glycol’s higher viscosity can increase suction losses.

Maintenance and Operation

-

Monitor seal integrity: Glycol can crystallize when exposed to air, leading to seal wear.

-

Flush the system periodically to prevent sludge or microbial buildup, especially in HVAC systems.

-

Check pump alignment and bearing lubrication—high viscosity increases mechanical load.

-

Inspect for corrosion or scaling in heat transfer circuits, particularly with older glycol formulations.

-

Verify concentration and pH regularly; degraded glycol can become acidic and attack pump components.

Typical Applications

-

HVAC and chilled water systems

-

Geothermal and solar thermal heating

-

Refrigeration and cold storage

-

Chemical process temperature control

-

De-icing and antifreeze distribution

-

Power and energy plant heat recovery loops

Summary

Pumping glycol requires attention to the fluid’s temperature-dependent viscosity, chemical composition, and compatibility with pump materials and seals.

Whether circulating a cooling loop, transferring antifreeze, or dosing glycol into a process line, selecting the right pump type—centrifugal for low viscosity, positive displacement for thicker blends—ensures efficient, reliable, and long-lasting operation.

With proper design and maintenance, pumps handling glycol deliver stable flow, minimal downtime, and optimal thermal system performance across a wide range of industrial and HVAC applications.