Pumping Solutions for CIP (Clean-in-Place) Fluids

CIP systems rely on pumps to move cleaning solutions through process equipment, pipework, tanks, and heat exchangers at the correct flow, pressure, velocity, and temperature. Because CIP fluids include caustics, acids, sanitising agents, and hot water rinse cycles, the pump must deliver stable hydraulic performance while withstanding chemical attack, thermal stress, and frequent cycling. A properly specified CIP pump is essential for consistent cleaning, validated hygiene, and reliable plant operation.

Characteristics of CIP Fluids

CIP fluids vary through the cleaning sequence, typically including:

- Hot water pre-rinse (60–80 °C)

- Caustic wash (e.g., NaOH at 1–4%, 70–85 °C)

- Intermediate water rinse

- Acid wash (e.g., nitric or phosphoric solutions, 0.5–1%, 60–70 °C)

- Final rinse and sanitiser (chemical or thermal)

These fluids differ in viscosity, pH, temperature, and conductivity. The pump must remain reliable across the full CIP cycle, not just one phase.

Technical Requirements for CIP-Duty Pumps

1. Materials & Chemical Compatibility

Because CIP fluids are chemically aggressive at elevated temperatures:

- Wetted materials are typically 316L stainless steel or approved high-alloy variants.

- Elastomers (EPDM, FKM, PTFE) are chosen for resistance to hot caustic and acid.

- Surface finishes must be smooth and crevice-free to prevent microbial retention.

2. High Flow Velocity & System Pressure

CIP cleaning relies on achieving turbulent flow (typically ≥1.5–2.0 m/s) through lines and equipment.

A CIP pump must:

- Maintain required differential pressure to overcome distribution loops, spray devices, and elevation.

- Deliver stable flow without pulsation to ensure consistent cleaning action.

3. Thermal Stability

Repeated cycling between cold rinse and hot caustic can cause:

- Thermal expansion stresses

- Seal wear

- Elastomer hardening

A CIP pump must be rated for continuous operation at the highest CIP temperature.

4. Hygienic Design

CIP pumps must support hygienic processing by offering:

- Fully drainable housings

- Smooth internal surfaces (Ra ≤ 0.8 µm in many industries)

- Minimal dead legs

- Seal arrangements compatible with CIP/SIP (single or double mechanical seals depending on process risk)

5. Maintenance & Reliability

CIP cycles may operate multiple times per day. Pumps must:

- Start and stop frequently without performance drift

- Purge or drain fully to prevent residual chemical crystallisation

- Maintain efficiency across thousands of cycles without seal failure

Why the Right Pump Matters

Choosing a pump designed specifically for CIP service ensures:

- Validated cleaning and hygiene compliance (food, beverage, dairy, pharma)

- Stable and repeatable flow for consistent cleaning performance

- Reduced maintenance thanks to correct metallurgy and seal selection

- Safer operation when handling hot, corrosive CIP solutions

- Lower lifecycle cost due to fewer failures and greater efficiency

A well-engineered CIP pump keeps both the cleaning system and the production process running reliably, ensuring high standards of sanitation with minimal downtime.

CIP cleaning fluids are normally slightly caustic so pumps that a degree of chemical resistance are required for these duties. AxFlow UK has a wide range of chemically resistant pumps that can run bidirectionally to clean the line if required.

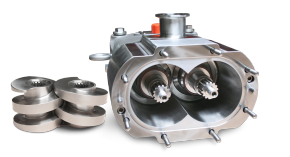

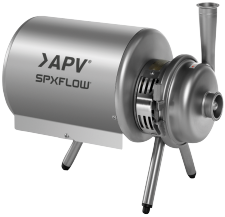

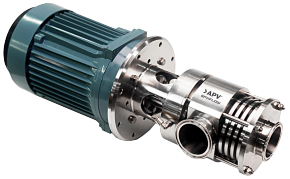

AxFlow's CIP pumps include centrifugal pumps, rotary lobe and twin screw that can be used for both product and CIP and can run in either direction.