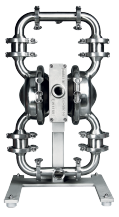

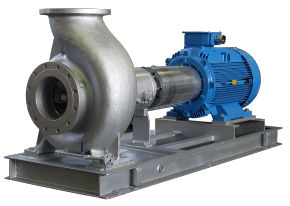

Pumping caustic solutions such as Caustic (Potash Potassium Hydroxide) and Caustic Soda (Sodium Hydroxide) can be challenging due to the variations in viscosity caused through changes in ambient temperature. Due to our large UK portfolio of PD and centrifugal pumps, coupled with our experience; AxFlow UK are always be in a position to offer the best pump for your caustic transfer requirements.

Pumping Solutions for Caustic (Alkaline) Solutions

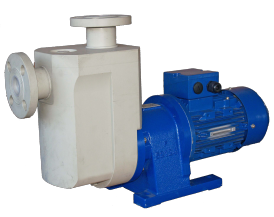

Pumping caustic solutions – such as sodium hydroxide (caustic soda), potassium hydroxide, and other high-pH cleaners – places specific demands on pump design and materials. These fluids are chemically aggressive, can cause stress cracking in unsuitable plastics and elastomers, and may crystallise or gel at lower temperatures or around leaks. A correctly specified caustic-duty pump must combine chemical resistance, safe containment, and stable hydraulics over the full range of concentration and temperature.

Typical Caustic Pumping Applications

Caustic solutions are widely used in:

- CIP and cleaning systems in food, beverage, and pharmaceutical plants

- pH correction and neutralisation in water and wastewater treatment

- Chemical processing for saponification, etching, and reagent preparation

- Surface treatment and metal finishing for degreasing and stripping

- Pulp & paper and textile processes as part of bleaching and finishing stages

Duties range from low-flow dosing to bulk transfer from IBCs, drums, and storage tanks.

Technical Requirements for Caustic Duties

Effective caustic pumping is defined by getting materials, sealing, and hydraulics right.

Materials & Compatibility

- Selection based on concentration, temperature, and impurities

- Common wetted materials include thermoplastics (PP, PVDF), PTFE-lined components, and suitable stainless steels or higher alloys where appropriate

- Elastomers (seals, diaphragms, O-rings) must be compatible with high pH to avoid swelling, embrittlement, or stress cracking

Sealing & Containment

- Robust mechanical seals, double seals, or seal-less designs (mag-drive, canned motor, AODD) reduce leakage risk

- Proper venting and drain arrangements help avoid crystallised caustic build-up around seals and fittings

- Correct gasket selection and bolting are critical for maintaining long-term seal integrity

Hydraulics & Operation

- Stable operation at the required flow and differential pressure, avoiding off-curve running that can increase heat and stress

- Consideration of NPSH and suction conditions, especially for hot, concentrated caustic that reduces available NPSH and may flash

- Design that allows drain-down and flushing to minimise product solidification and simplify maintenance

Why the Right Caustic Pump Matters

An incorrectly specified pump for caustic duty can lead to rapid corrosion, seal failures, crystallisation around leak points, and unsafe operating conditions. A pump engineered specifically for caustic service will:

- Maintain consistent, predictable flow for cleaning, dosing, or process control

- Reduce leaks, exposure risk, and unplanned downtime

- Extend component and seal life through correct materials and design

- Lower total lifecycle cost by minimising failures and maintenance interventions

In short, matching pump technology and materials to the specific caustic solution and duty conditions turns a high-risk fluid into a controlled, reliable part of the process.