How piston pumps work

Piston and plunger pumps are types of positive displacement reciprocating pumps that move and pressurise fluids by means of a reciprocating element — a piston or plunger — within a sealed cylinder.

They are designed for applications requiring high pressure, precise flow control, and excellent volumetric efficiency, making them ideal for oil and gas, chemical dosing, hydraulic systems, and high-pressure cleaning.

Working Principle

Both piston and plunger pumps operate on the same reciprocating displacement principle — alternating suction and discharge strokes move a fixed volume of fluid through the system each cycle.

1. Suction Stroke

-

As the piston or plunger moves backward, it increases the cylinder volume.

-

This creates a pressure drop, causing the suction valve to open.

-

Fluid is drawn into the cylinder from the suction line.

2. Discharge Stroke

-

When the piston or plunger moves forward, it reduces the cylinder volume.

-

The suction valve closes and the discharge valve opens under pressure.

-

The trapped liquid is forced out through the discharge port at high pressure.

Each cycle delivers a discrete, measured volume of fluid — meaning flow rate is directly proportional to speed and almost independent of discharge pressure.

Piston vs. Plunger Pump Design

| Feature | Piston Pump | Plunger Pump |

|---|---|---|

| Reciprocating element | Piston with sealing rings or cups | Plunger with stationary packing seals |

| Seal location | Moves with the piston | Fixed in the cylinder head |

| Pressure capability | Medium (up to ~200 bar) | High (up to ~3,000 bar or more) |

| Applications | Hydraulic presses, irrigation, metering | High-pressure cleaning, oilfield injection, process dosing |

Key difference: In a piston pump, the seal moves with the piston; in a plunger pump, the seal is stationary, allowing operation at much higher pressures and longer seal life.

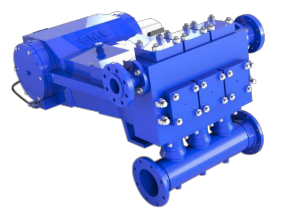

Main Components

-

Power End: Converts rotary motion from a motor or engine into reciprocating motion using a crankshaft and connecting rod.

-

Fluid End: Contains the cylinder, valves, suction/discharge ports, and sealing arrangement.

-

Check Valves: One-way valves that control fluid direction — typically ball or spring-loaded disc types.

-

Packing/Seals: Maintain pressure integrity and prevent leakage around the piston or plunger.

Performance Characteristics

-

Flow Rate: Determined by stroke length, piston area, and speed.

-

Pressure: Determined by system resistance; can reach thousands of bar in plunger designs.

-

Efficiency: Volumetric efficiency typically >95%, even at high pressures.

-

Flow Uniformity: Can be improved with multiple plungers (triplex, quintuplex, etc.) for smoother delivery.