How plunger pumps work

A retracting plunger creates a suction effect in the liquid end and opens the suction valve. The medium flows into the liquid end. The plunger then moves forward. The plunger displaces the available volume through its own volume and increases the pressure of the fluid to be pumped. The suction valve closes and the pressure valve opens the way into the process area for the pressurized fluid.

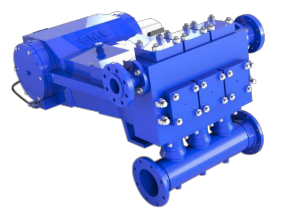

The forward and backward movement of the plunger repeats itself continuously and opens or closes the valves. Depending on the application, the cycles are repeated up to several hundred times per minute. To prevent an intermittent flow of fluid, so-called suction side and discharge sided pulsation dampers are used, which ensure uniform flow and reduced pulsations. Several plungers can be used in a single pump in combination to increase the flow rate and for a more even flow rate. They feed the common process area via the same pressure pipe. The number of plungers in the pump varies depending on the design and application.

The plungers are driven hydraulically or by a crankshaft with connecting rods and crosshead extensions. If there are several plungers, the angular positions on the crankshaft can be distributed in such a way that the pressure peaks in the pump are staggered.