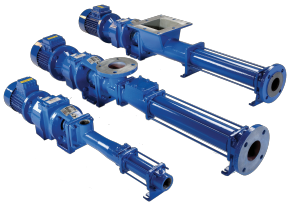

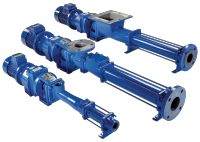

How to select progressive cavity pumps

- Viscosity: The more viscous a fluid is, the lower the operating speed of the pump should be (PC pump efficiency is highest at slower speeds).

- Temperature: Stator material must correlate with the fluid temperature. Not only this, but the size of the pump is key here as rises in fluid temperature will result in the expansion of the elastomer stator. Moreover, it is also key to mention that high viscosity and temperature sensitive materials may result in maintenance concerns with other pumps that may provide a faster rate of flow.

- Flow rate & Pressure: Although PC pumps may be disregarded as they are typically more efficient when operating at lower speeds. More viscous, abrasive, and temperature-sensitive materials can cause problems in pumps that may offer higher flow rates, thus indicating PC pumps are excellent for such pumping applications.

Things to consider

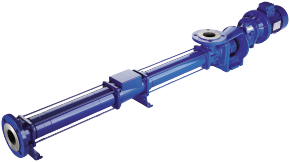

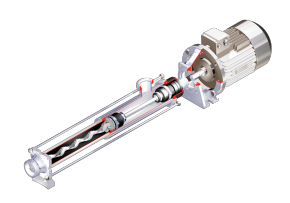

Selecting the right progressive cavity pump involves careful consideration of various factors to ensure optimal performance and efficiency in specific applications.It is critical to assess the characteristics of the fluid being pumped, including viscosity, abrasiveness, and chemical composition. Progressive cavity pumps are versatile and can handle a wide range of fluids, but selecting the appropriate elastomer stator material is crucial for compatibility and longevity. Flow rate and pressure requirements are key performance parameters, and the pump's size and design should align with the desired operational parameters.

Additionally, assessing the temperature conditions of the application is vital, as it can impact the pump's material selection and overall performance. The type of solids present in the fluid, if any, influences the choice of rotor and stator geometry to prevent clogging and maintain efficiency. Consideration of the pump's construction materials, such as the type of metal used for the rotor and stator, ensures durability and resistance to corrosive elements.

selection and overall performance. The type of solids present in the fluid, if any, influences the choice of rotor and stator geometry to prevent clogging and maintain efficiency. Consideration of the pump's construction materials, such as the type of metal used for the rotor and stator, ensures durability and resistance to corrosive elements.

Evaluating the available installation space, maintenance requirements, and ease of access for servicing will contribute to the long-term reliability of the pump. Finally, consulting with pump manufacturers or experts to discuss specific application details can provide valuable insights and assistance in selecting the most suitable progressive cavity pump for the intended purpose.

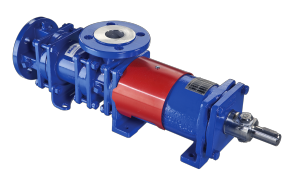

Abrasive Fluids

The higher the abrasive properties of the fluid the better to select a larger pump and run it slower than a smaller and faster pump. Although this may come across as more expensive, this is likely to improve your return on investment, and in the long-term reduce costs on maintenance expenses. Moreover, If you are operating with more abrasive fluids it is suggested that you reduce the pressure per stage.

For more information on pumping Abrasive fluids click here...

In order to maximise resistance to wear, it is ideal to select a design to keep the linear fluid velocity less than seven feet per second, but realize that solids can fall out of suspension at velocities less than four feet per second.