What is Process Condensate?

Process condensate is a byproduct of various industrial processes where steam is used for heating or other purposes. This condensation results from cooling down the steam after it has performed its function. Often thin and dry, process condensate poses specific challenges due to its low viscosity, low Net Positive Suction Head (NPSH), and the presence of corrosive elements.

Challenges in Pumping Process Condensate

- Low NPSH: Process condensates generally have low NPSH, requiring specialized pumps capable of handling these conditions.

- Poor Lubrication: These condensates lack natural lubrication, increasing wear and tear on pump components.

- Corrosive Elements: The presence of corrosive elements demands pumps resistant to chemical corrosion.

- Low Flows: Condensate flows are often minimal, requiring pumps that can handle low flow rates effectively.

Handling Process Condensate

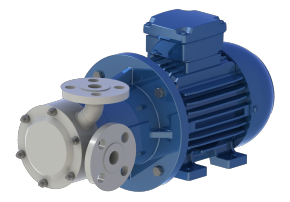

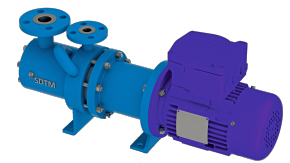

At AxFlow, we understand the intricacies of handling process condensate. Our range of specialized condensate pumps is designed to meet these challenges head-on. With a focus on low NPSHa tolerance, superior lubrication capabilities, and resistance to corrosive elements, our pumps ensure seamless operations in diverse industrial environments.

Applications of Process Condensate

- Industrial Heating: Used in industries for space heating and various industrial processes.

- Steam Systems: Condensate recovery systems in steam-based heating systems.

- Waste Heat Recovery: Capturing and utilizing waste heat through condensate recovery.

AxFlow's expertise lies in providing reliable solutions for pumping process condensate, ensuring efficient and safe operations for industries across Europe. Trust in our specialized pumps to handle the unique challenges posed by condensate applications.

Oil & Gas condensate

Wellhead Production

- Move a mixture of crude oil, condensate, water, and sometimes gas from the wellhead to initial processing equipment (like separators).

- Typical pumps: Multiphase pumps, progressive cavity pumps (PCP).

Separation and Processing Facilities

- After gas-liquid separation, condensate (and oil) is pumped to storage, further processing, or pipelines.

- Typical pumps: Centrifugal pumps, positive displacement pumps.

- Special considerations: Condensate is light and volatile — pump design must handle high vapor pressure and avoid cavitation.

Pipeline Transportation

- Boost pressure to move oil or condensate long distances through pipelines (often hundreds of miles).

- Typical pumps: High-capacity centrifugal pipeline pumps or reciprocating booster pumps.

Offshore Platforms

- Pump condensate to floating storage units (FSUs), tankers, or subsea pipelines.

- Transfer liquids between processing modules on FPSOs (Floating Production, Storage, and Offloading units).

- Challenges: Space, weight, maintenance constraints.

Storage and Loading

- Move oil/condensate from storage tanks to export pipelines, trucks, railcars, or marine terminals.

- Circulate liquids within tank farms to maintain product quality.

- Typical pumps: Vertical turbine pumps, horizontal centrifugal pumps.

Gas Processing Plants

- After gas processing, condensate is separated and pumped to storage or sale.

- For example In NGL (natural gas liquids) recovery units or cryogenic gas plants.

- Pumps: Similar to those used in oil service, with special attention to vapor pressure and volatility.

Enhanced Oil Recovery (EOR) / Re-injection

- In some cases, light hydrocarbons (including condensate) may be re-injected into reservoirs to maintain pressure or enhance recovery.

- Pumps: High-pressure injection pumps.