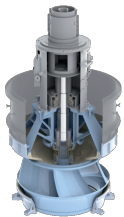

hOW axial flow pumps work

Axial flow pumps are a type of dynamic (centrifugal) pump that move fluid parallel to the pump shaft, rather than radially as in centrifugal pumps. They are designed for high-flow, low-head applications where large volumes of liquid must be transported efficiently — such as flood control, cooling water circulation, irrigation, and wastewater treatment.

In simple terms, they operate like a propeller in a pipe: the rotating impeller blades impart velocity directly along the flow axis, generating continuous movement of fluid.

Principle of Operation

-

Fluid Entry

The liquid enters the pump axially (in line with the shaft) through a suction bell or inlet guide. Flow is usually conditioned to be uniform and free of turbulence before reaching the impeller. -

Impeller Action

The axial impeller—a propeller with several blades fixed to a hub—rotates at high speed. As the blades spin, they act like airfoils, creating a lift force that accelerates the fluid in the axial direction.-

The lift generated by each blade depends on its angle of attack, curvature, and rotational speed.

-

Because the fluid motion is almost entirely parallel to the shaft, the pump develops velocity head rather than pressure head.

-

-

Energy Conversion

The kinetic energy imparted to the fluid by the impeller is partially converted into pressure energy by the discharge casing or diffuser vanes.-

Unlike radial pumps, which rely heavily on centrifugal acceleration, axial pumps achieve head primarily through momentum change along the axis.

-

-

Discharge

The fluid exits axially through the discharge column or pipe. Diffuser vanes are often used to straighten the flow and recover additional pressure energy by decelerating the fluid efficiently.

Hydraulic Characteristics

-

Flow Direction: Parallel to the shaft (axial).

-

Head Range: Typically 1–10 m per stage (can be higher with multi-stage designs).

-

Flow Capacity: Very high — up to tens of thousands of cubic metres per hour.

-

Efficiency: Excellent in high-volume, low-head service; often 80–90% hydraulic efficiency.

-

Specific Speed: Very high (Ns > 10,000 in US units), meaning the pump is optimized for high flow, low head conditions.