How to select axial flow pumps

Selecting the right axial flow pump requires balancing hydraulic performance, installation layout, material compatibility, and operational conditions to ensure reliability, energy efficiency, and long service life.

Define the Hydraulic Requirements

Flow Rate (Q)

-

The defining parameter for an axial flow pump.

-

Determine the required discharge flow rate (m³/h or L/s) based on process demand or system throughput.

-

Because these pumps are optimized for high volume, sizing the flow capacity accurately avoids oversizing and wasted energy.

Total Dynamic Head (TDH)

-

Typically low — between 1 to 10 meters per stage.

-

Include static lift, friction losses, and minor losses from fittings or valves in your calculation.

-

Ensure the selected pump operates near its Best Efficiency Point (BEP) at the required head.

NPSH (Net Positive Suction Head)

-

Check that the available NPSH exceeds the pump’s required NPSH to prevent cavitation.

-

Axial flow pumps can be installed vertically or semi-submerged to maintain proper suction conditions.

Consider the Fluid Properties

Fluid Type

-

Clean water, seawater, slurries, or industrial effluents each have different impacts on materials and hydraulics.

Temperature

-

High temperatures may affect bearing lubrication and material expansion; choose materials accordingly.

Solids Content

-

For abrasive or sediment-laden fluids, use hardened impellers, wear-resistant coatings, or rubber-lined casings.

Corrosiveness

-

Select corrosion-resistant materials such as stainless steel, duplex steel, or bronze for seawater and chemical service.

Select the Installation Configuration

Vertical Configuration

-

Common for deep sumps or water intake wells.

-

Space-saving, self-venting, and provides excellent suction conditions.

Horizontal Configuration

-

Suitable where headroom is limited.

-

Easier maintenance but requires priming systems.

Submersible or Mixed-Flow Variants

-

Used in flood control or drainage systems where the pump must operate submerged or in variable water levels.

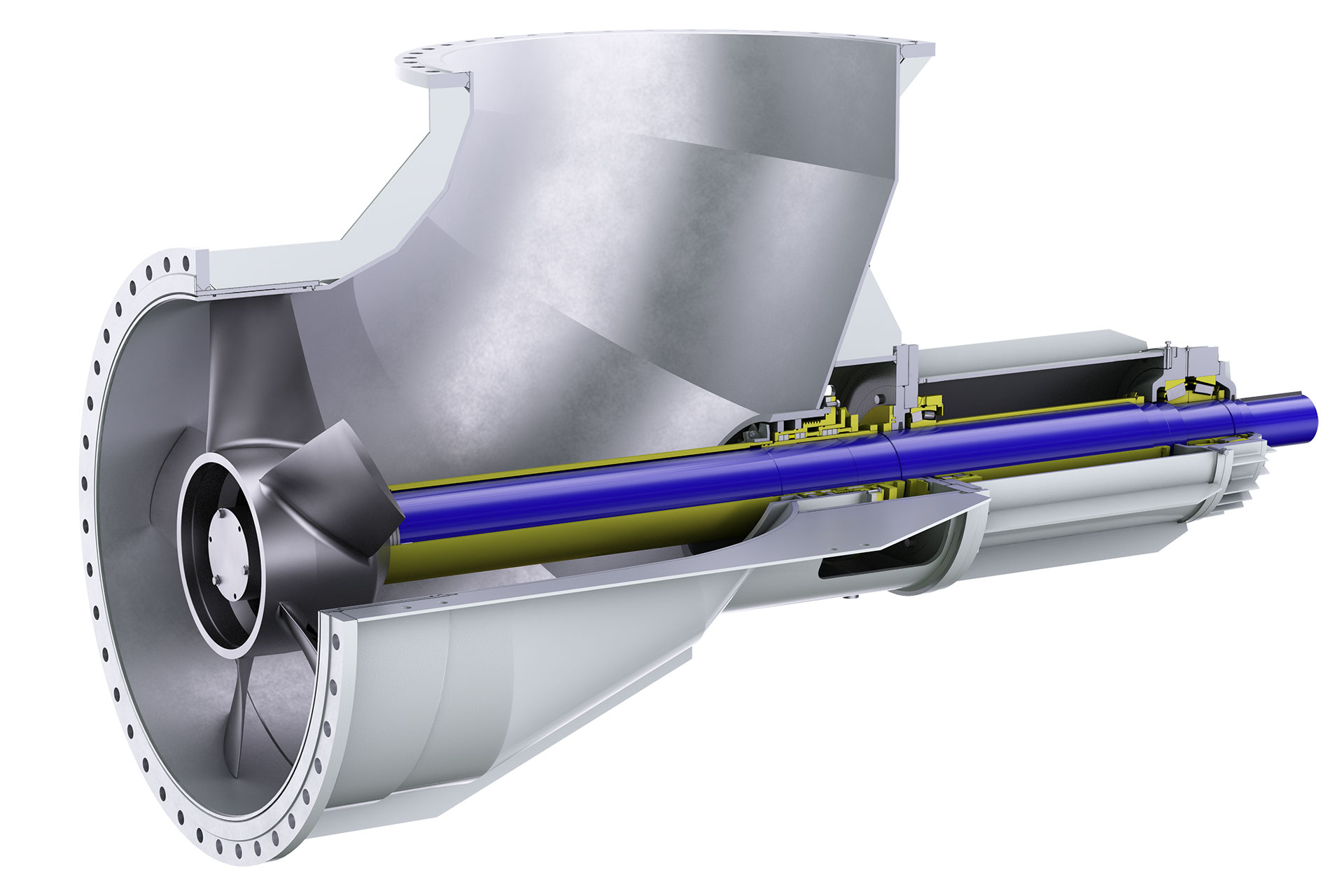

Evaluate Mechanical and Design Features

-

Impeller Type: Choose between fixed-pitch (simple and durable) or adjustable-pitch (variable performance control).

-

Bearings: Water- or grease-lubricated; ensure compatibility with service fluid.

-

Drive Arrangement: Options include vertical electric motors, right-angle gear drives, or diesel engines.

-

Column Construction: Modular column pipes can be customized to site depth and support structure.

Material Selection

Choose materials based on the operating environment:

| Application | Recommended Materials |

|---|---|

| Clean water | Cast iron, carbon steel |

| Seawater | Bronze, duplex stainless steel |

| Industrial waste | Rubber-lined steel, stainless steel |

| Slurries or abrasives | Hard iron, ceramic coatings |

Efficiency and Control

-

Operate near the Best Efficiency Point (BEP) to minimize vibration and wear.

-

Use variable-pitch impellers or VFDs (Variable Frequency Drives) for flow control without throttling losses.

-

Select a pump with the highest efficiency at the expected duty point to reduce operating costs over time.