How to maintain eccentric disc pumps

Routine Inspection and Monitoring

Visual and Operational Checks

-

Inspect the pump body, cover, and suction/discharge ports for leaks, corrosion, or wear.

-

Check for unusual vibration or noise, which can indicate internal wear or misalignment.

-

Monitor flow rate, pressure, and power consumption; deviations may signal internal bypassing or disc wear.

-

Observe temperature at the bearing housing — excessive heat often points to bearing or coupling issues.

Performance Tracking

-

Record flow, discharge pressure, and motor load periodically.

-

Compare readings against baseline operating data to detect early performance changes.

Lubrication and Bearings

-

Eccentric disc pumps rely on hydrodynamic film lubrication from the pumped fluid — always ensure adequate liquid presence before startup.

-

Never run the pump dry; doing so can cause immediate damage to the disc and liner.

-

Check external bearings (if fitted) for wear and replenish or replace grease according to manufacturer guidelines.

-

For gearmotor-driven models, ensure the gearbox oil is clean and at the correct level.

Disc and Liner Maintenance

-

Inspect the disc surface and liner regularly for scoring, erosion, or chemical attack.

-

Replace components when wear exceeds the manufacturer’s tolerance — excessive clearance reduces volumetric efficiency and can cause pulsation.

-

Ensure the disc moves freely within the liner and that there is no mechanical contact during rotation.

-

Use only OEM wear parts to maintain proper clearances and material compatibility.

Shaft Seals and Elastomers

-

Examine mechanical seals or packing glands for leakage.

-

Replace seals showing visible wear, cracking, or chemical degradation.

-

Always use seal and elastomer materials compatible with the pumped medium (e.g., PTFE, FKM, EPDM).

-

For hazardous or high-temperature fluids, check seal flush systems for correct operation.

Alignment and Drive System

-

Check motor-to-pump alignment during installation and after maintenance. Misalignment causes vibration, seal failure, and bearing wear.

-

Inspect couplings and flexible elements for cracks or fatigue; replace worn parts immediately.

-

Ensure that the pump rotates in the correct direction—reversed rotation can damage the pumping element.

Cleaning and Flushing

-

After handling viscous, sticky, or reactive liquids, flush the pump and lines with a compatible cleaning fluid.

-

Operate at reduced speed during flushing to prevent cavitation and ensure thorough cleaning.

-

For food, pharmaceutical, or hygienic service pumps, follow CIP/SIP (Clean-in-Place/Sterilise-in-Place) protocols as recommended by the manufacturer.

Storage and Standby Care

When the pump is not in service for extended periods:

-

Drain the system and dry internal surfaces to prevent corrosion or contamination.

-

Fill with a protective lubricant or inert fluid if required.

-

Rotate the pump manually every few weeks to keep internal components free-moving.

Scheduled Overhaul

-

Perform a complete inspection at least annually (or per manufacturer’s maintenance schedule).

-

Disassemble the pump and clean all internal components.

-

Inspect the disc, liner, bearings, and seals for wear or corrosion.

-

Replace any damaged or worn parts with certified replacements.

-

-

Verify proper torque on fasteners and reassemble according to specifications

Longevity

Eccentric disc pumps tend to be low-maintenance and deliver the superior wear compensation, strong suction and low shear that is mandatory when handling these unique materials, with many Mouvex units having provided over 30 to 40 years of service with essentially no maintenance concerns.

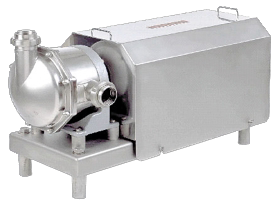

Clean-in-place (CIP)

Eccentric disc pumps also feature simple, efficient clean-in-place/sanitize-in-place operation that does not require the vertical drain porting that drains lobe pumps of a large amount of their efficiency. In most cases, the CIP process starts with a water flush with concentrations of different cleaning solutions, such as a mild caustic, and perhaps a reheating of solutions that are circulated through the pump, piping and valves, and ending with a final rinse. In some instances, steam can be utilised in the place of water or other cleaning solutions.

With no need for mechanical seals, there aren't any surfaces present where products that are difficult to seal and prone to crystallization can adhere and cause damage, thus removing such maintenance concerns.