How to select centrifugal pumps

Selecting the right centrifugal pump is crucial for achieving efficient, reliable, and cost-effective fluid transfer. A properly selected pump not only meets the required flow and head but also operates near its best efficiency point (BEP) — reducing energy consumption, vibration, and maintenance costs.

Centrifugal pumps are used across industries to handle everything from clean water to corrosive chemicals, slurries, and viscous liquids. Correct selection depends on matching the pump’s hydraulic and mechanical characteristics to the process requirements, fluid properties, and system conditions.

Define the Application Requirements

Start with a clear understanding of the system duty point — the flow rate and total head the pump must deliver.

-

Flow rate (Q): Volume of liquid to be pumped, typically in m³/h or L/s.

-

Total head (H): The energy the pump must impart to the fluid — including static lift, friction losses, and discharge head.

-

Operating mode: Continuous, intermittent, variable speed, or batch operation.

The duty point determines pump size, impeller diameter, and motor power rating.

Determine the Fluid Characteristics

The nature of the liquid being pumped directly affects pump type, materials, and sealing system.

| Property | Considerations |

|---|---|

| Viscosity | Higher viscosity reduces efficiency — consider low-speed designs or PD pumps for thick fluids. |

| Temperature | Affects material selection and seal type (high temperatures may require cooling). |

| Specific gravity | Impacts power requirement and shaft load. |

| Corrosiveness | Select corrosion-resistant materials such as stainless steel, bronze, or thermoplastics. |

| Abrasiveness | Choose hardened materials, wear rings, or rubber linings to resist erosion. |

| Solids content | Open impeller or recessed impeller designs handle solids better. |

Calculate the System Head Curve

A good pump selection requires plotting both:

-

The pump curve (flow vs head provided by the manufacturer).

-

The system curve (head required by the piping and process system).

The point where these two curves intersect defines the operating point. Ideally, this should lie close to the pump’s BEP (Best Efficiency Point) to ensure:

-

Smooth hydraulic operation

-

Minimal vibration and wear

-

Low energy consumption

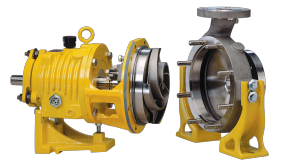

Select the Pump Type

There are many types of centrifugal pumps; the correct choice depends on your application:

-

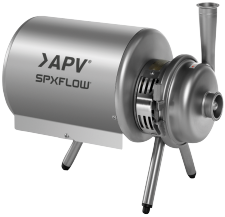

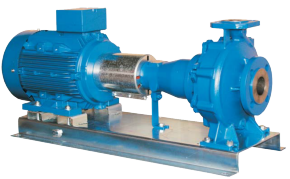

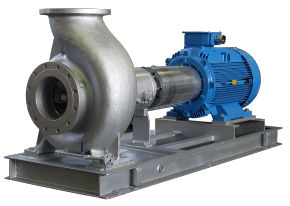

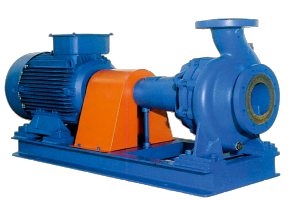

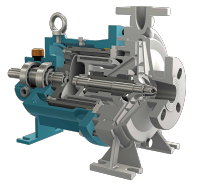

End-suction pump: General-purpose design, compact, easy to maintain.

-

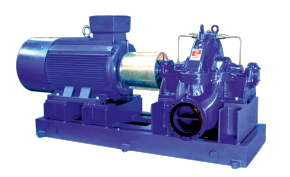

Split-case pump: For large flow rates and high reliability; double-suction impeller reduces axial thrust.

-

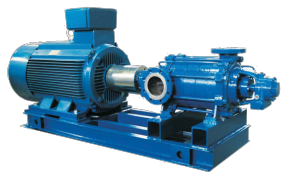

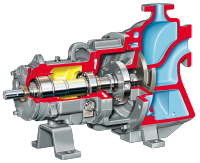

Multistage pump: For high-pressure applications (boiler feed, mine dewatering).

-

Self-priming pump: For suction lifts or intermittent operation.

-

Vertical turbine or submersible pump: For deep-well or high-flow water transfer.

-

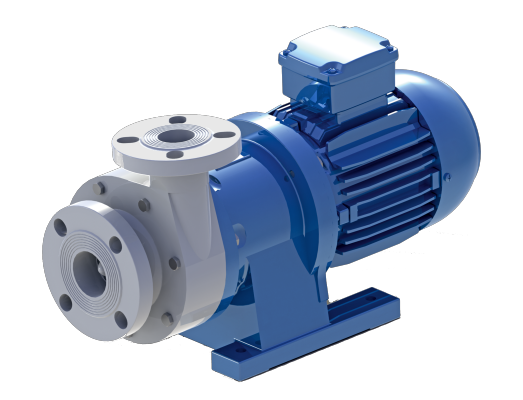

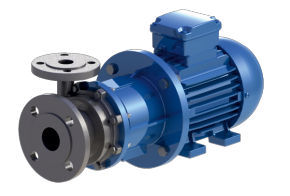

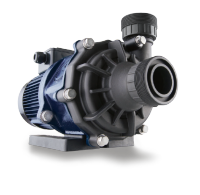

Magnetically driven or sealless pump: For hazardous, toxic, or leak-sensitive fluids.

Select Construction Materials

Material selection depends on the fluid’s chemistry, temperature, and pressure:

| Fluid Type | Recommended Materials |

|---|---|

| Clean water | Cast iron or bronze |

| Seawater | Bronze or duplex stainless steel |

| Acids / corrosive chemicals | PVDF, PTFE, or 316 stainless steel |

| Abrasive slurries | Hard iron, high-chrome alloys, rubber-lined casing |

| Thermal oils | Carbon steel or stainless steel with heat barrier design |

Choosing the correct materials extends service life and prevents costly corrosion failures.

Select the Seal and Bearing Arrangement

-

Mechanical seals: Preferred for most industrial services; double or cartridge seals may be needed for hazardous or high-temperature fluids.

-

Packing glands: Suitable for water or non-critical duties; allow controlled leakage for lubrication.

-

Sealless designs (mag-drive): Eliminate leakage risk in toxic or corrosive services.

-

Bearings must be properly sized, lubricated, and protected from process heat or contamination.

Consider Efficiency and Energy Use

Operating efficiency has a direct impact on lifecycle cost.

-

Select pumps that operate near their BEP under normal conditions.

-

Use variable frequency drives (VFDs) for systems with variable demand.

-

Avoid oversized pumps — throttling wastes energy and increases wear.

-

Review motor and impeller sizing together to ensure optimal performance.

Installation and Maintenance Factors

Ease of maintenance and system layout are key to long-term reliability:

-

Ensure sufficient space for dismantling and service access.

-

Align the pump and motor shafts precisely to prevent bearing and seal wear.

-

Include isolating valves and pressure gauges for maintenance and performance monitoring.

-

Verify that suction piping design prevents air ingress and provides adequate NPSH (Net Positive Suction Head).

Safety and Compliance

-

For hazardous or flammable fluids, ensure pumps comply with ATEX or ISO standards.

-

Incorporate secondary containment or leak-detection systems where required.

-

Confirm compatibility with local environmental and process safety regulations.

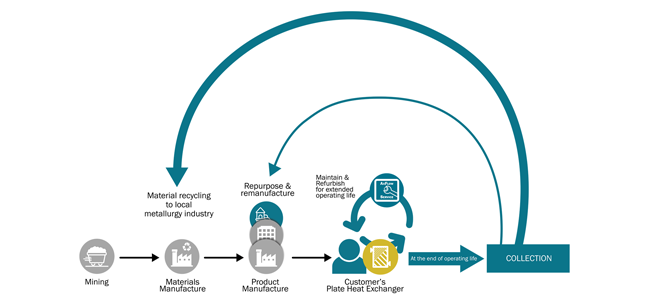

JOIN US IN WORKING SMART – SUSTAINABLE SMART

Our vision, mission, our promise – fluidity.nonstop and our values FAR SIGHTED, GOOD TO WORK WITH and MAKING THINGS HAPPEN – they all keep us pulling in the same direction. That's efficient....

Read moreCentrifugal Mag Drive Pumps

AxFlow offer a large range of magnetically driven centrifugal pumps

read more about centrifugal mag drive pumps