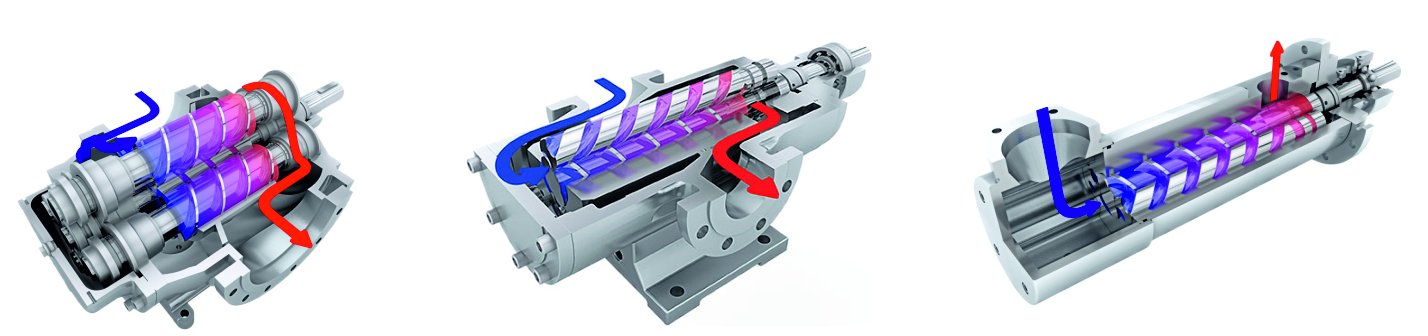

Hygienic screw pumps are positive displacement pumps that use one or several screws to move fluids or solids along the screw(s) axis.

Screw Pumps

1 series from 1 manufacturers

AxFlow specialise in hygienic twin screw pumps for the food and berage sector.

Advantages of screw pumps

- A simple design makes it heavy duty with minimal wear.

- Twin screw pumps can run in either direction allowing them to deliver a bi-directional flow.

- Smooth handling, operating a range of flows and pressures.

- Versatility with ability to pump at a range of flow rates, pressures, liquid types and viscosities

- Self-priming characteristics

- High tolerance for entrained gases or air.

- Eliminate slip pulsations in low viscous, high pressure applications

- Low NPSH requirement when emptying tanksWide range of flow capabilities (run speeds up to 3500 RPM)

Typical applications for screw pumps

Twin screw pumps are most suitable for hyienic aplications that would benefit from a pump that can handle fluids with different viscosities. The most common of such appliactions is where the pump is required to pump the product and also CIP fluids. This application is very common in confectionary production settings.

Most multiple-screw pump designs are self-priming and are able to effectively work with low suction pressure. They also tend to be gas tolerant and are able to handle free and entrained gases without vapor locking. Low internal fluid velocity and the gentle meshing of the rotors also contribute to low shear rates, which is especially important for sheer-sensitive emulsions.

Twin screw pumps are also fantastic for Product & CIP pumping applications.

WHY BUY SCREW PUMPS FROM AXFLOW

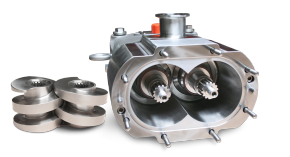

The Waukesha Universal TS range is a new and innovative positive displacement twin screw pump for hygienic applications. This precision pump offers a gentle flow and the ability to pump both product and CIP therefore reducing overall process costs considerably.

The Waukesha Universal Twin Screw pump is designed to handle a vast range of liquids, ranging from very thin to highly viscous fluids making it suitable for applications across different industries, such as food and beverage, pharmaceuticals, chemicals, and petrochemicals. The twin screw pumps ability to handle a diverse range of fluids decreases the need for multiple types of pumps, thus simplifying your overall fluid handling process.

How to select screw pumps

Different types of Screw Pumps:

- Single Screw Pumps: These are typically regarded as Progressive Cavity Pumps. Although they are similar to screw pumps, they feature a rotor and stator that differ from the screw component found in screw pumps.

- Twin Screw Pumps: also known as as double screw pumps, are ideal for high head, high flow applications and in particular commonly used for transfer duties.

- Triple Screw Pumps: These screw pumps are typically used for smaller pumping systems such as lubrication operations.

The geometries of the single or multiple screws and the drive speed will affect the pumping action required.

Screw Pump capacity tends to be measured using 3 factors:

- Pump Dimension

- Dimensions of the surface of the screws

- Rotational speed of the rotor due to specific volume transferred with every revolution

If you pick out the incorrect screw pump, is likely to lead to unnecessary difficulties. The wide range of screw pumps all have their own advantages. It is key to understand their respective characteristics, in order to better achieve energy saving, material saving, increase efficiency or meet some special requirements.