how twin screw pumps work

Twin screw pumps are positive displacement, self-priming pumps that use two intermeshing screws rotating in opposite directions to transfer fluid continuously and smoothly.

They are designed for gentle, pulse-free handling of liquids across a wide viscosity and temperature range — making them ideal for food processing, chemical, marine, and oil & gas applications.

Unlike many other pump types, twin screw pumps can handle liquid, gas, or multiphase mixtures, making them highly versatile in demanding process environments.

Main Components

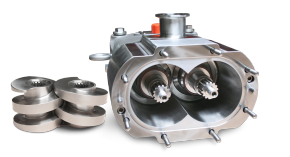

A typical twin screw pump consists of:

-

Two precision-engineered screws (rotors): Mounted parallel to each other and driven synchronously.

-

Pump housing: Encloses the screws and forms the flow chamber.

-

Timing gears: Ensure non-contact rotation between screws, eliminating metal-to-metal wear.

-

Inlet and outlet ports: Positioned axially for linear fluid movement through the pump.

-

Bearings and seals: Support and isolate the rotating elements for reliable operation under pressure.

Working Principle (Detailed)

The twin screw pump operates on the positive displacement principle, with two counter-rotating screws creating sealed cavities that move fluid axially from suction to discharge.

1. Suction Phase

-

As the two screws begin to rotate in opposite directions, cavities form at the inlet where the screw threads disengage.

-

This expansion creates a partial vacuum, drawing fluid into the spaces between the screw threads and the pump casing.

2. Transfer Phase

-

The fluid is trapped within the cavities formed by the screw flanks and the casing.

-

As rotation continues, these cavities move axially from the suction side to the discharge side.

-

Because the screws are synchronized by external timing gears, they do not touch each other or the casing, allowing smooth, wear-free operation.

-

This ensures no internal backflow, maintaining precise volumetric displacement.

3. Discharge Phase

-

At the discharge end, the screw threads re-engage, reducing cavity volume and forcing the trapped fluid out under pressure.

-

The process repeats continuously, delivering a steady, pulse-free flow proportional to the pump’s rotational speed.

This design allows for bidirectional operation, meaning the same pump can handle filling and emptying functions simply by reversing the rotation direction.

Hydraulic and Mechanical Characteristics

-

Flow type: Smooth, linear, and pulse-free.

-

Flow rate: Directly proportional to screw speed.

-

Pressure capability: Typically up to 16–40 bar (some designs exceed 100 bar).

-

Viscosity range: Handles fluids from <1 cP (thin solvents) to >1,000,000 cP (heavy oils or pastes).

-

Temperature range: Up to 350°C depending on materials and design.

-

Self-priming: Excellent suction lift capability, typically up to 8–9 metres.