Sanitary Pumps

AxFlow are established UK leaders in the field of sanitary pumps and hygienic pumps for pharmaceutical applications.

Pumping personal care products such as creams, cosmetics, toothpaste, foams and oral hygeine presents a range of challenges. The need for gentle, low shear pumping action. Accuracy, high levels of hygiene. AxFlows wide range of positive displacement pumps, allows us to offer a larger number of suitable options with saintary designs.

What Are Sanitary Pumps?

Sanitary pumps are specially designed fluid-handling devices used in industries where hygiene, cleanliness, and contamination control are critical. These pumps are constructed from materials such as stainless steel and feature smooth, crevice-free surfaces to prevent bacterial growth and allow for easy cleaning and sterilisation. They are commonly used in the food & beverage, pharmaceutical, dairy, cosmetic, and biotech sectors.

Why Are Sanitary Pumps Important in the Production Process?

Sanitary pumps play a vital role in maintaining product safety, quality, and compliance throughout production. Here's why they're essential:

-

Contamination Prevention: Designed to prevent cross-contamination by meeting strict hygiene standards (such as EHEDG, FDA, or 3A).

-

Easy to Clean: Most sanitary pumps support CIP (Clean-in-Place) or SIP (Sterilise-in-Place) processes, reducing downtime and ensuring thorough sanitation.

-

Product Integrity: Their gentle pumping action helps preserve the quality of delicate, shear-sensitive products like creams, yoghurts, or biological liquids.

-

Compliance and Certification: Sanitary pumps are built to comply with regulatory requirements, helping manufacturers meet health and safety standards.

-

Efficient Flow Control: Whether dosing, transferring, or filling, these pumps ensure consistent and precise fluid movement in critical production stages.

WHY BUY SANITARY PUMPS FROM AXFLOW

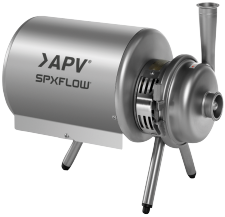

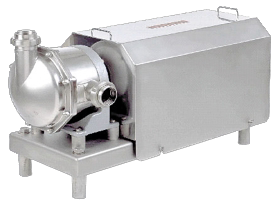

AxFlow UK boasts the widest range of sanitary and food grade pumps in the UK. Our range includes many hygienic centrifugal pumps and sanitary positive displacement models for use as high viscosity pumps. AxFlow is the exclusive UK distributor for APV.

Our hygienic pump portfolio covers low shear rotray lobe and eccentric disc pumps, AOD pumps, hygienic stainless steel centrifugal pumps, and vane pumps. AxFlow offers many EHEDG pumps and 3A certified pumps as well as using FDA and 1935 approved materials.

Food Grade Centrifugal pumps for use in food and beverage production.

Hygienic AODD pumps designed and built with materials suitable for food production in mind.

AxFlow UK offers several ranges of food grade eccentric disc pumps.

All of our external circumferential disc pumps are ATEX rated range offers the benefits of low shear pumping with ATEX certification.

AxFlow's range of realax peristaltic pumps are all available as ATEX rated pumps.

Vane pumps can find a range of problem solving applications in the food industry.

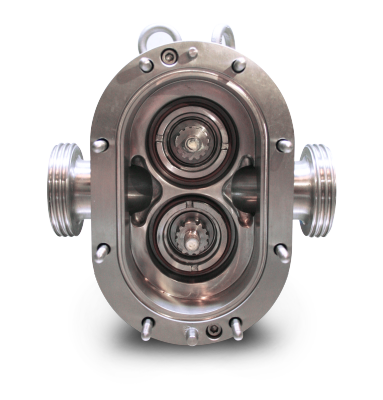

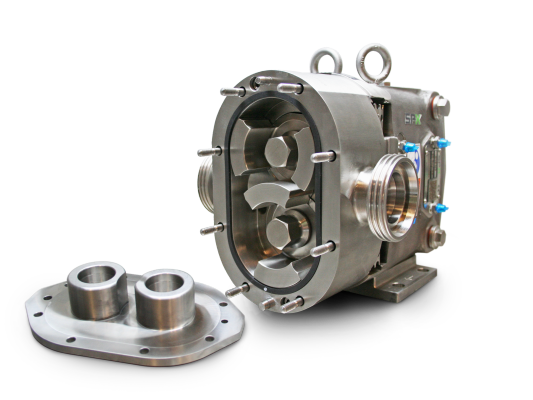

Sanitary and hygienic rotary lobe and external circumferential piston pumps.

When selecting sanitary pumps for specific applications, factors such as pump material, design, cleaning capabilities, and regulatory compliance should be considered to meet industry standards and maintain product quality. It's important to work with pump manufacturers and suppliers who have expertise in providing solutions for sanitary and hygienic processes.

Axflow UK are able to pump some of the most Viscous and sensitive fluids.

Click the image to find out more about our sanitray pump repair.

The importance of Sanitary pump maintenance

Maintaining sanitary pumps is crucial to ensure the integrity and safety of processes in industries where hygiene and sterility are vital. Regular maintenance routines involve meticulous cleaning, sterilization, and inspection of all components to prevent the possibility of contamination and uphold overall product quality. Thorough disassembly, cleaning with approved solutions, and proper reassembly are critical steps. Additionally, adherence to industry regulations, documentation of maintenance procedures, and continuous training for personnel are essential to guarantee consistent and effective operation of sanitary pumps.

System Cleaners provide all segments in the food and beverage industry with state-of-the-art manual and automated cleaning solutions

Exclusive APV Distributor

AxFlow are APV's exclusive distributor for the UK. The APV product portfolio includes a wide range of pumps, valves, heat exchangers, mixers and homogenizers.

read more about APV's exclusive distributorHygienic Pump Design

The food industry is extensively regulated and at AxFlow UK, we ensure to offer the best approved equipment to you and your business. Please find our overview of the different hygienic approval...

read more about hygienic pump designAseptic Pumps

AxFlow offer a range of pumps suitable for aseptic manufacturing processess.

read more about aseptic pumpsSanitary Rotary Lobe Pumps

sanitary and hygienic rotary lobe and external circumferential piston pumps.

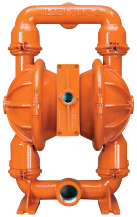

read more about food grade rotary lobe pumpsHygienic AODD Pumps

AxFlow offers a range of AODD pumps for sanitary and hygienic applications

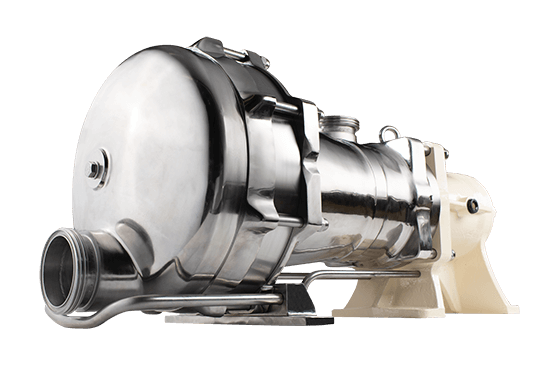

read more about aodd pumpsHygienic Eccentric Disc Pumps

AxFlow UK offers several ranges of food grade eccentric disc pumps.

more about food grade eccentric disc pumps