High-temperature oils—such as thermal transfer fluids, heat transfer oils, lubricants, or process media—are used in applications where temperatures can exceed 150°C to over 400°C.

Pumping these fluids safely and efficiently requires specialized pump designs, materials, and sealing systems capable of handling extreme heat, thermal expansion, and viscosity changes without compromising reliability.

Typical applications include heat transfer systems, chemical processing, asphalt plants, power generation, and food manufacturing.

Key Challenges of Pumping Hot Oils

Handling high-temperature oils introduces several engineering challenges that must be addressed in pump selection and system design:

-

Thermal Expansion:

Components expand at high temperatures, affecting clearances and alignment. Pumps must be built with materials and tolerances that accommodate this. -

Viscosity Variation:

As temperature increases, oil viscosity decreases. Pump performance and efficiency can change drastically with fluid temperature, requiring careful selection of impeller geometry and speed. -

Seal Integrity:

Standard mechanical seals may fail due to thermal shock, dry running, or elastomer degradation. High-temperature sealing systems with metal bellows, graphite packing, or double seals with barrier fluids are often required. -

Lubrication and Cooling:

Bearings and seals need proper cooling and lubrication to avoid overheating. Some pumps use air cooling fins, external oil lubrication, or water-cooled seal chambers to manage temperature. -

Material Compatibility:

Pump casings, shafts, and fasteners must resist thermal stress, oxidation, and corrosion. Carbon steel, stainless steel, or ductile iron are typical choices for thermal oil service.

why buy from AxFlow

See below our mag drive & canned pumps catalogue which provides extensive information on pumping high temperature oils, and can guide you on the ideal pump for your application.

See below our mag drive & canned pumps catalogue which provides extensive information on pumping high temperature oils, and can guide you on the ideal pump for your application.

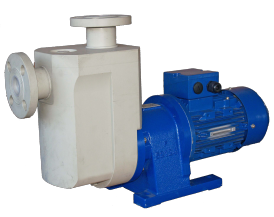

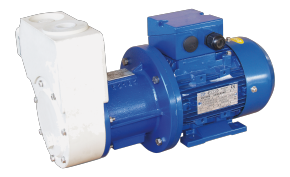

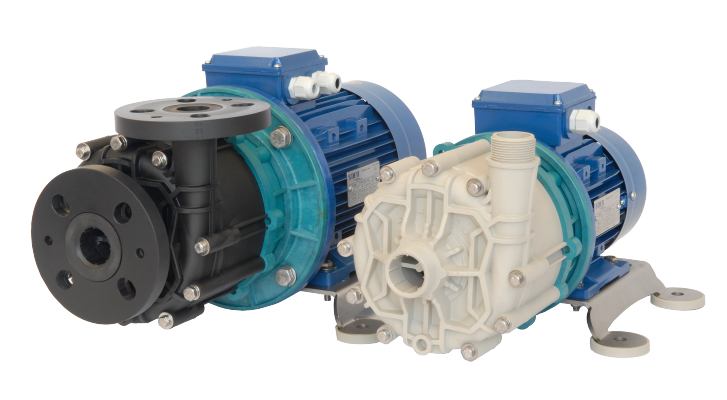

Mag Drive pumps provide a range of advantages when pumping high temperature liquids:

- Magnetic drive pumps remove the need for traditional shaft seals, which tend to be prone to wear as well as leakages, which especially occurs in high-temperature applications. This sealless design allows for improved reliability and decreases the risk of oil leakage or contamination. As well as this, Mag drive pumps feature a hermetically sealed containment shell that isolates the pumped fluid from the external environment. This prevents vapor emissions, leaks, and contamination, making them suitable for pumping high-temperature oils

- Mag drive pumps are typically constructed from materials such as stainless steel or titanium which are fortunately compatible with various oils and are able to withstand high temperatures without degradation, thus improving the pump's longevity and prevents corrosion.

- Mag drive pumps offer precise control over flow rates and fluid handling, allowing for accurate dosing and metering of high-temperature oils. This is essential in applications where precise fluid delivery is required to maintain process integrity and quality

Maintenance Recommendations

-

Inspect seals and bearings regularly for signs of heat damage or oil leakage.

-

Monitor oil quality: Oxidized or degraded thermal oil can form carbon deposits, which reduce efficiency and cause fouling.

-

Check alignment and shaft clearances after long shutdowns or temperature changes.

Design and Installation Considerations

-

Seal Cooling:

Use cooled or vented seal chambers to protect sealing components from overheating. -

Thermal Isolation:

Incorporate heat barriers or lantern rings between the pump casing and bearing housing. -

Piping Design:

Allow for thermal expansion of pipework; use flexible couplings or expansion joints where necessary. -

Startup Procedure:

Preheat oil slowly to prevent thermal shock to pump components. Avoid cold starts with highly viscous oil. -

Safety Measures:

Equip systems with temperature and pressure monitoring, relief valves, and drain lines for safe operation and maintenance.

-

Ensure proper cooling of the bearing housing and lubrication systems.

-

Flush and clean the system periodically to remove sludge and carbon buildup