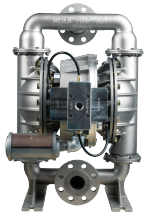

AODD Pumps

AxFlow are a leading UK supplier of AODD pumps.

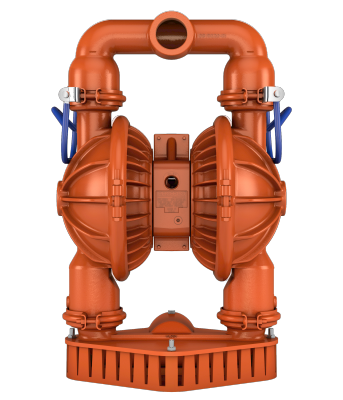

AxFlow are one of the leading UK suppliers of AODD pumps with over 50 years experience. AxFlow UK has a wide range of Air Operated Double Diaphragm pumps from Wilden and Almatec. How AODD pumps work.

Air Operated double diaphragm pumps are widely used for their simple, portable construction and their ability to dry prime and handle solids.

Air Operated Diaphragm pumps are employed in a host of fluid transfer applications ranging from circulation duties in cleanroom environments to sludge pumping. AOD Pumps are intrinsically safe by design, offering a wide range of material and elastomer options:

Hygienic AODD Pumps

AxFlow offers a range of AODD pumps for sanitary and hygienic applications

read more about aodd pumpsATEX AODD Pumps

AxFlow offer both metal and plastic ATEX rated AODD pumps

read more about atex aodd pumpsAODD Fault Diagnosis

Not working properly? Here's our fault diagnosis guide.

read more about aodd fault diagnosisWilden Pump Repair Service

AxFlow offer a professional and documented Wilden Pump Repair Service that only uses original Wilden spare parts.

Read more about Wilden pump repair servicePump Hire

AxFlow offer a range of specialist hire pumps for offshore applications.

read more about pump hire