AxFlow has the widest ranges of rotary vane pumps in the UK

Rotary Vane Pumps

10 series from 3 manufacturers

-

- Acids

- Alcohols

- Ammonia

- Bitumen

- Caustic Solutions

- Chocolate

- Cooling Water

- Corrosive Liquids

- Cryogenic Liquids

- Diesel Fuel Oil

- Dye Pigment

- Ferric Chloride

- HydrochloricAcid

- Liquid CO2

- Low NPSH

- LPG

- Phosphoric Acid

- Radio Active Fluids

- Refrigerants

- Separated Oil Processing

- Silver Nitrate

- Solvents

- Spirits

- Sulphuric Acids

- Thin Liquids

- Toxic Liquids

-

- Adjustable-Flow

- Automatic

- Canned

- Chemically Resistant

- CIP

- Close-Coupled

- Compact

- Containment

- Corrosion-Proof

- Direct-Drive

- Double-Acting

- Electric

- Explosion-Proof

- Flange

- Heavy-Duty

- High System Pressure

- High Temperature

- High-Performance

- Horizontal Mount

- Intrinsically Safe

- Low Shear

- Low-Noise

- Magnetic Drive

- Mechanical

- Mechanical Seal

- Modular

- Multi-Stage

- Pulse-less

- Rotary

- Sanitary

- Seal-less

- Self-priming

- Single-Stage

- SIP

- Variable Speed

- Vertical

- Vertical-Mount

Do you need help finding the right pump that meets your needs?

We have experienced experts who are ready to help you!

Get in touch hereWhat are Rotary Vane pumps

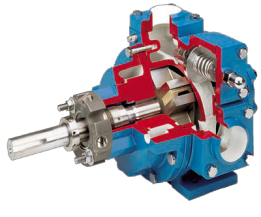

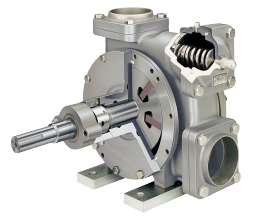

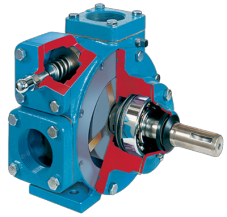

Rotary vane pumps are a very popular form of positive displacement pump that have been used around the world for many decades. They consist of vanes mounted on to a rotor that rotates inside the pump chamber. In some cases, these vanes can have variable length and/or be tensioned to maintain contact with the walls as the pump rotates.

How do rotary vane pumps work

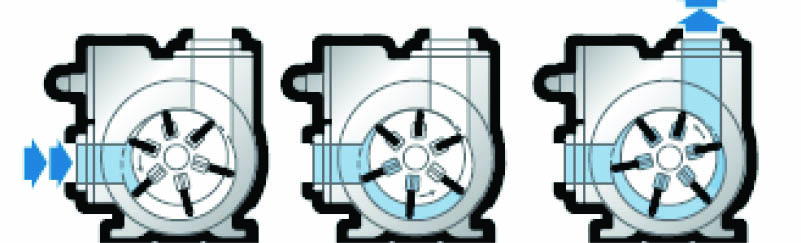

Standard rotary vane pumps operate on the principle of the eccentricity between the shaft and the pump casing bore (stator). Rotary vane pumps come in two types: the flexible vane and sliding vane.

FLEXIBLE VANE PUMPS

In flexible vane pumps the vanes are made from a malleable material. The tips of the vanes used in flexible vane pump are lobe shaped and when rotating they flex in order to maintain contact with the walls of the stator, thereby trapping the fluid in small pockets or cavities. When the discharge pipe is reached the trapped fluid is released from the pockets.

SLIDING VANE PUMPS

In sliding vane pumps, the vanes are made from a rigid material and do not flex when rotating. The rigid vanes that are free to slide into or out of slots in the pump rotor by way of springs or pressure-activated pins in the rotor. As the rotor turns, the vanes move out of the rotor slots creating a void at the inlet port and drawing fluid in. The fluid is transferred from the inlet port to the discharge port between the vanes. At the outlet, the fluid is discharged and the pumping chamber is reduced and the vanes slide back into the

Vane pump Applications

Rotary vane pumps are used in many different applications due to their all-round versatility. Typical applications include fluids that display varying levels of viscosity, have high or low temperature levels, are non-lubricating or could be made from ingredients that can be aggressive and cause damage to the pump.

When it comes to light, non-lubricating fluids such as alcohols and solvents then vane pumps are very often the best solution as they are self-lubricating and can (with the correct design) cope with low net positive suction head (NPSH).

CHOOSING THE RIGHT vane PUMP

When it comes to selecting a pumping system, the choice commonly comes down to rotary positive displacement and centrifugal types, as both types can often be used for the same applications.

By virtue of their inherent energy and mechanically efficient designs, positive displacement rotary and sliding vane pumps are perfectly suited to offering operators immediate high value advantages and solutions in fulfilling their energy saving initiatives. In reviewing a list of the most common system characteristics that need to be considered in pumping applications, positive displacement pumps outperform centrifugal pumps is almost all of them.

If you have a relatively low flow and a relatively high-pressure requirement, or if you require the pump to be self-priming, then a vane pump will often be the best solution.

When selecting a rotary vane pump you should, among other things, consider whether it should be:

- Using alternating or direct current

- Oil-sealed or dry

Do you need help choosing the right pump for your industry and needs? Get in touch, our team of knowledgeable experts would be happy to advise you!

BENEFITS OF ROTARY VANE PUMPS

Rotary vane pumps deliver a gentle low shear action so that the structure of the pumped fluid is not affected.

By virtue of their inherent energy and mechanically efficient designs, positive displacement rotary and sliding vane pumps are perfectly suited to offering operators immediate high value advantages and solutions in fulfilling their energy saving initiatives. In reviewing a list of the most common system characteristics that need to be considered in pumping applications, positive displacement pumps outperform centrifugal pumps is almost all of them.

Depending on the technology chosen, rotary vane pumps may offer:

- Ability to self-prime.

- Constant flow that is relatively independent of changes in system pressure.

- Constant flow that is relatively independent of changes in viscosity.

- Ability to handle low and medium viscosity products.

- Can handle thin liquids at relatively higher pressures.

- Develop a good vacuum.

- Ability to run dry for short periods.

- Higher efficiency across varying system pressures.

WHERE TO USE ROTARY VANE PUMPS

Rotary vane pumps are used in many different applications due to their all-round versatility. They can deliver flows up to 450 m3/hr and differential pressures of 14 bar. They are typically found in dispensing applications, transferring fuels, low flow circulation duties and some specialist applications such as pumping chocolate.

Rotary Vane pumps are also commonly used for pumping viscous fluids such as oils and syrups, as well as this Vane pumps can are excellent at handling a variety of solvents such acetone. When it comes to light, non-lubricating fluids such as alcohols and solvents then vane pumps are very often the best solution as they are self-lubricating and can (with the correct design) cope with low net positive suction head (NPSH).

Rotary Vane Pump Maintenance

Proper rotary vane pump maintenance is essential to maintain volumetric efficiency, prevent vane wear, and ensure reliable operation in industrial and process applications. As positive displacement pumps, rotary vane pumps rely on precise internal clearances and vane condition for consistent performance.

Key Maintenance Practices

- Inspect vanes for wear, cracking, or loss of length; replace worn vanes to maintain sealing and efficiency

- Monitor lubrication oil level and quality in oil-lubricated designs

- Check seals, shaft seals, and gaskets for leakage

- Monitor noise, vibration, and flow stability, which may indicate vane or bearing wear

- Keep suction lines clean and airtight to maintain adequate NPSH and prevent cavitation

Planned Maintenance

- Replace vanes and seals at scheduled intervals

- Flush the pump to remove deposits or contaminants

- Verify pump-to-motor alignment after maintenance

Rotary Vane Pump Service & Repair

We provide inspection, vane replacement, repair, and refurbishment services for rotary vane pumps across chemical, industrial, and process applications.

WHY BUY ROTARY VANE PUMPS FROM AXFLOW

AxFlow UK has been supplying rotary vane pumps for over 50 years as a result we are one of the leading experts when it comes to rotary vane pumps in the UK.

AxFlow offers 10 different ranges of vane pumps from three manufacturers; Blackmer, Gruppo Aturia, and Mouvex giving us the widest selection of vane pumps in the UK. Our range of vane pumps includes cast iron and stainless steel models, mag drive options, vane pumps designed for low viscosity liquids such as LPG, API 676 and pulseless pumps.