Vertical Axial Flow Pumps flows to 15.000 m3/hr and heads of 10 m

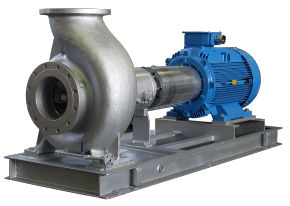

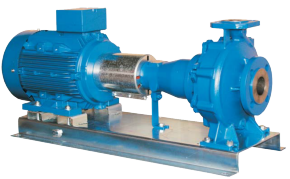

Centrifugal Pumps

74 series from 12 manufacturers

-

- Adhesives

- Agriculture

- Aviation

- Bakery and confectionery

- Beauty & Personal Care

- Brewing and beverages

- Building Services

- Ceramics

- Chemical

- Confectionery

- Convenience food

- Dairy

- Detergents

- Distilleries

- Docks

- Drinking Water

- Fertilizers

- Food & Beverage

- Heating, Water & Sanitation

- Marine

- Meat Processing

- Mining

- Nuclear Power Plants

- Offshore

- Oil & Gas

- Oil Fats & Mayonnaise

- Paints & Resins

- Paper Mills

- Petrochemical

- Pharmaceutical

- Plastic

- Power Generation

- Research & Development

- Surface / Pit

- Surface Finishing

- Textile

- Transportation

- Underground

- Wastewater

- Water Treatment

-

- Analysis

- Booster

- Circulation

- Cleaning

- Control

- Conveying

- Cooling

- Descaling

- Desinfection

- Dewatering

- Diagnostic

- Discharge

- Distribution

- Dosing

- Drain

- Drainage

- Dredging

- Dual Dispensing

- Extraction

- Feed

- Filling

- Filtration

- Flow Control

- Greasing

- Grinding

- Handling

- Heating

- High-Pressure

- High-Temperature

- High-Volume

- Injection

- Irrigation

- Level Control

- Lift

- Lifting

- Loading

- Low-Pressure

- Lubrication

- Medium-Pressure

- Metering

- Mixing

- Off-loading

- Powder Coating

- Pressurisation

- Process

- Processing

- Recirculation

- Recovery

- Refueling

- Replacement

- Rinsing

- Sampling

- Settling

- Spraying

- Tempering

- Transfer

- Treatment

- Ultra High-Pressure

- Unloading

- Volumetric Dispensing

- Washing

- Water-Jet Cleaning

- Water-Jet Cutting

-

- Abrasive Liquids

- Acetate

- Acids

- Adhesives

- Alcohols

- Aluminium Oxide Slurry

- Ammonia

- Beer

- Biological Broths and Slurries

- Bitumen

- Carbon Fibers

- Caustic Solutions

- China Clay Slurry

- CIP Fluids

- Clay

- Cooling Water

- Corrosive Dyes

- Corrosive Liquids

- Cryogenic Liquids

- Crystalline Slurry

- Dairy Products

- Detergents

- Diesel Fuel Oil

- Drinking Water

- Dye Pigment

- Emulsions

- Ethylene Glycol

- Ferric Chloride

- Fertilizers

- Foam Protein

- Fruit Concentrates

- Gels

- Glycol

- High Temperature Oils

- HydrochloricAcid

- Irrigation Water

- Lake Water

- Latex

- Light Fluids

- Lime

- Liquid CO2

- Low NPSH

- Low Viscosity Liquids

- LPG

- Milk

- Molasses and Syrups

- Non-Newtonian Fluids

- Oil, Fats and Mayonnaise

- Paints

- Paints Resins

- Personal Care Products

- Pet Food

- Phosphoric Acid

- Plastic

- Process Condensate

- Produced Water

- Radio Active Fluids

- Redox

- Refrigerants

- Rubber

- Sauces

- Seawater

- Sensitive and Viscous Fluids

- Separated Oil Processing

- Sewage

- Silver Nitrate

- Soaps and Detergents

- Solids and Abrasives

- Solvents

- Spirits

- Sulphuric Acids

- Surface Water

- Surfactants

- Synthetic Fibers

- Thermal Oil

- Thin Liquids

- Thixotropic Fluids

- Toluene

- Toxic Liquids

- Ultra Pure Water

- Vegetable Oils

- Vinegar

- Viscose

- Viscous Liquids

- Wastewater

- Water

- Water Hardness

-

- Abrasion Resistant

- Adjustable-Flow

- Automatic

- Booster Sets

- Canned

- Chemically Resistant

- CIP

- Close-Coupled

- Compact

- Containment

- Corrosion-Proof

- Direct-Drive

- Double-Acting

- Electric

- Explosion-Proof

- Flange

- Heavy-Duty

- High System Pressure

- High Temperature

- High-Efficiency

- High-Flow

- High-Performance

- Horizontal Mount

- In-Line

- Intrinsically Safe

- Low Shear

- Low-Noise

- Magnetic Drive

- Mechanical

- Mechanical Seal

- Mixed Flow

- Mobile

- Modular

- Motorless

- Multi-Stage

- Non-Metal

- Oil-Free

- Plastic Lined

- Pulse-less

- Rotary

- Rugged

- Sanitary

- Seal-less

- Self-priming

- Semi Submersible

- Single-Stage

- SIP

- Solids Handling

- Submersible

- Variable Speed

- Vertical

- Vertical-Mount

Do you need help finding the right pump that meets your needs?

We have experienced experts who are ready to help you!

Get in touch hereWhat are centrifugal pumps

Centrifugal pumps are a type of pump that uses a rotating impeller to increase the velocity of a fluid. The increased velocity results in a flow of fluid in the desired direction. Such pumps are used in a range of different industries for transferring fluids,which may include water, chemicals, and petroleum products.

Centrifugal pumps are the most useful all round pump with a balanced combination of flow and pressure capability. Centrifugal pumps represent approximately 80% of the pumps insalled around the globe.

Why Buy Centrifugal Pumps From AxFlow

With over 80 ranges of centrifugal pumps from 11 different manufacturers, AxFlow is one of the leading suppliers of centrifugal pumps in the UK

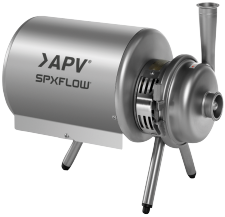

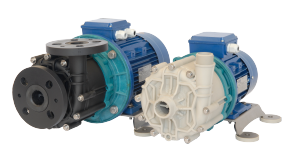

Our range of centrifugal pumps covers almost every type of centrifugal pump that you can think of. This includes DIN pumps, ISO pumps, hygienic centrifugal pumps, API centrifugal pumps, multistage centrifugal pumps, centrifugal pumps that handle solids and canned centrifugal pumps.

With such a large choice of centrifugal pumps we will offer you the most appropriate pump for your application.

Just click on the link....

• DIN 24255 (EN 733) • ISO 5199-2858 • API • ATEX •

• Magnetic Drive • Multistage • Double Suction • Canned • Plastic Lined

• Self Priming • Chemically Resistant • Hygienic • Solids Handling

Our centrifugal pump partners

Gruppo Aturia DIN 2455, ISO 5199, boiler feed, mag drive, API 610, API 685, canned pumps for the nuclear industry, bore hole pumps, APV Hygienic pumps Wernert ISO 5199 lined pumps. Warman Soilds handling pumps Argal Plastic mag drive, plastic mech sealed, plastic column pumps. Waukesha Hygienic pumps. Hermetic Canned pumps. Hayward Gordon Soilds handling pumps. Finder API 610 pumps. Varisco Industrial self priming pumps. Bungartz Specialist low NPSHa pumps.

Where can centrifugal pumps be used

Centrifugal pumps are utilised through a variety of different industries as a result of their efficiency and versatillity.

They tend to be used in the transfer of low viscosity fluids, with some of the main applications where centrifugal pumps are used include water supply and distribution systems, wastewater treatment plants as well as oil and gas, chemical processing, power generation, and food and beverage production. Centrifugal pumps tend to be ideal for processes that require a continuous and steady flow of fluids, making them a essential in a range of different processes across varyingsectors.